Our 150-year anniversary celebrates our dedicated employees, our wonderful Adirondack community and our long-lasting partnerships.

Finch’s First 150 Years

Finch is an American manufacturing success story, operating in Glens Falls, New York, for 150 years. We’ve succeeded by constantly reinventing the way we work, to exceed our customers’ expectations.

1865-1880

Jeremiah and Daniel Finch, along with Samuel Pruyn, purchase the Glens Falls Company mill and form Finch, Pruyn Company. Soon after, they acquire the Wing Mill, where Finch sits today. The company manufactures lumber, canal boats, lime and prized black marble, which has the honor of being incorporated into the Washington Monument.

1920-1930

The company’s focus turns to manufacturing newsprint and hanging paper, a base stock for wallpaper. The last black marble is quarried in 1923, lime production ends in 1929, and sawmills cease operation. The last boat to run the Feeder Canal carries Finch paper.

1930-1940

During the Great Depression, the company invests in 10 new grinders to improve wood-chip production, while a water turbine generates electricity for use in the mill. The company’s retail division opens an appliance store.

1940-1950

The company constructs a bleaching facility and converts its product mix from newsprint to high-quality magazines and book paper. The paper is used by Reader’s Digest, Boys' Life, and TV Guide. The last river drive carrying logs from the Adirondack Mountains down the Hudson River is in 1950.

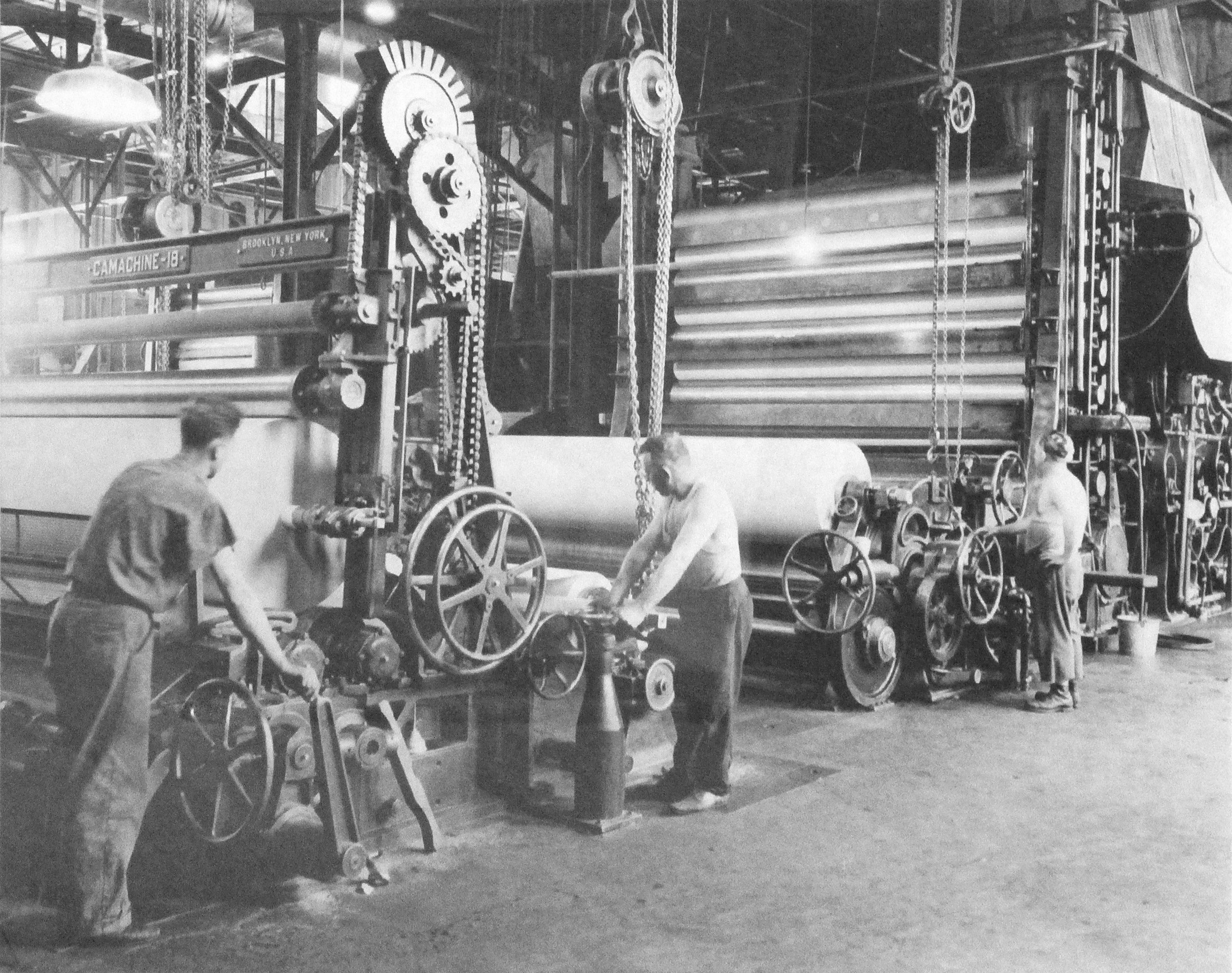

1950-1960

All three paper machines are completely rebuilt. A new sulfite pulping process begins that utilizes hardwoods in addition to softwoods. During this time, Finch, Pruyn is the largest private landowner in New York state, with 202,045 acres of timberland.

At Finch Paper, our company's story is the bedrock that fortifies our present and guides our future.

1990-2000

The company rebuilds its largest paper machine to increase production, adds a sheeter and installs an elemental chlorine-free system. A larger Glens Falls warehouse is built, and a Chicago warehouse starts operations in 1994. Recycled and digital papers are introduced, including Finch Casablanca Opaque and Finch Fine iD.

2000-2010

The family business Finch, Pruyn is renamed Finch Paper LLC in 2007 by new owners, Atlas Holdings LLC and Blue Wolf Capital Partners. Finch sells its Adirondack lands to The Nature Conservancy, who in turn hire Finch foresters to continue management. The company’s first production inkjet paper is introduced.

2010-2015

Paper machine Number 1 has a new headbox installed; the wood-processing operation is upgraded with new equipment and assets; many significant energy-saving projects are completed; and the company becomes 100-percent Boiler MACT compliant. The product portfolio is significantly expanded, including the addition of high-bright business papers, converting grades and inkjet substrates.

1880-1900

Finch, Pruyn purchases its first Adirondack tract, more than 13,000 acres, and quickly accumulates well over 100,000 acres of Adirondack forestland, becoming the largest lumber business on the Hudson. Finch, Pruyn’s pound-sterling mark brands the logs driven down the river.

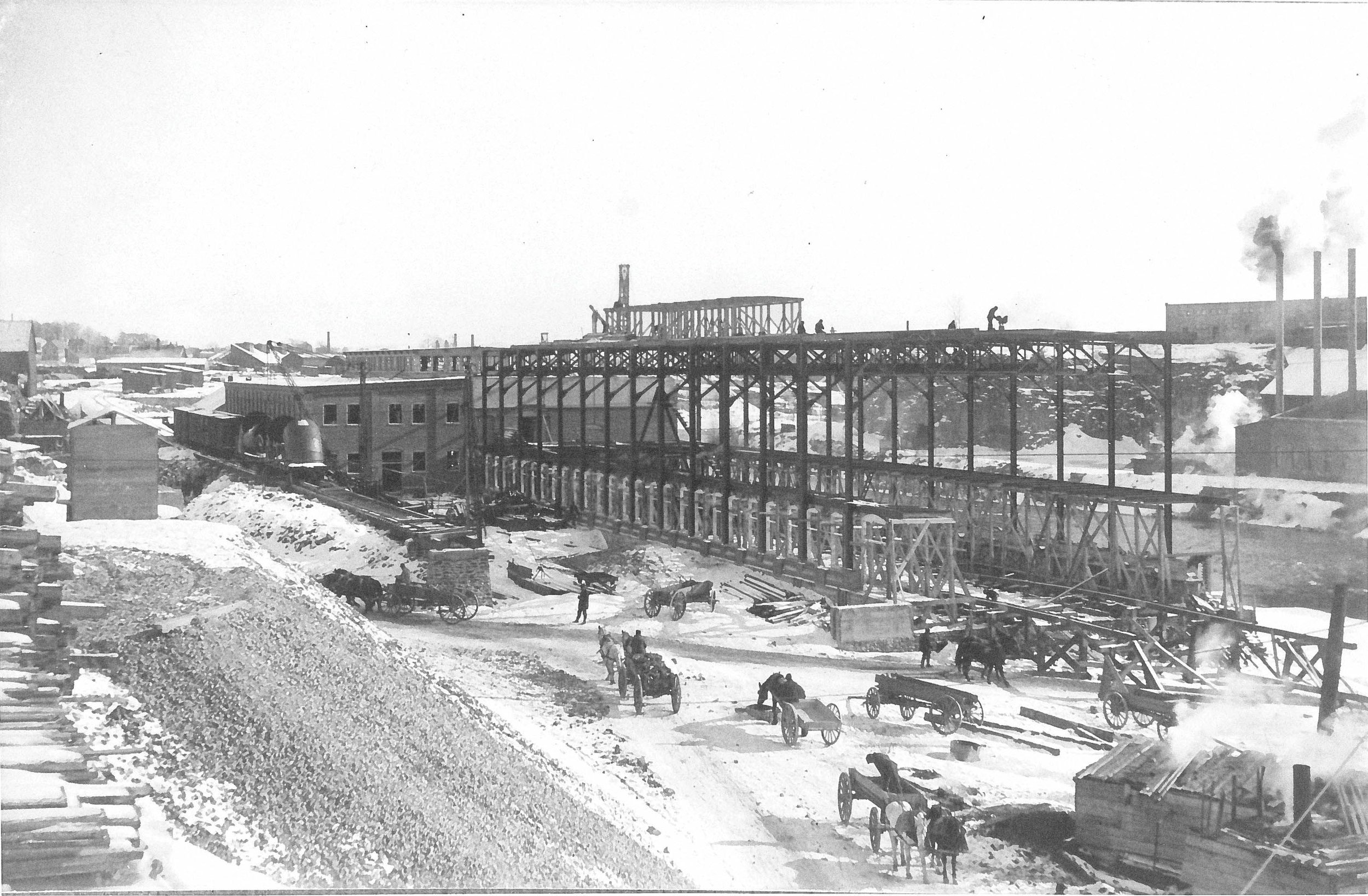

1900-1910

Finch, Pruyn and Company merges four companies into one and becomes incorporated. A groundwood pulp mill using spruce and balsam, and a paper mill are constructed. Paper production begins in September 1905. The first order of newsprint paper goes to “New York American.”

1910-1920

Howard Churchill, the nation’s first professional forester, is hired to pioneer a program of managed, multiple-use forestry. The company adds a sawmill on Henry Street and a third paper machine. Finch, Pruyn’s landmark office building, built with limestone quarried from the paper mill site, is completed in 1911.

1960-1970

Production doubles with a fourth paper machine in 1965. The mill switches from coal to cleaner fuel oil, and converts to an odor-free bisulfite pulping process. Papers for envelopes, maps, greeting cards, gift wrap, lace paper, box liners and labels are made along with Finch Offset, Finch Bond and Finch Mimeo. Finch Opaque is introduced in 1963.

1970-1980

Biomass power boilers are installed to produce on-site energy from renewable resources, and an advanced wastewater treatment plant is constructed. Finch, Pruyn’s retail division acquires a building-supply company and opens Warner Pruyn Home Center with a drive-through warehouse.

1980-1990

The power plant begins using a cogeneration steam turbine; a precipitated calcium-carbonate plant is constructed; and an automatic roll finishing system and two sheeters are added. An alkaline-based pulping process is introduced in 1982. Finch Fine debuts in 1983, and the first cover weight is produced in 1984.